Electrode Paste:

The petroleum coke and the asphalt are dehydrated and melted in the melting tank, and are mixed into a kneading pot in proportion, and then calcined. It has the characteristics of low resistivity and is used as a conductive material in electric furnace equipment such as iron alloy furnace and calcium carbide furnace. Electrode paste can be said to be a simple and technically complicated product in carbon production. After being kneaded and molded, the electrode paste became a finished product. Unlike other carbon and graphite products, when defects occur in the previous process, it can be compensated by baking, graphitization or even an impregnation process. The electrode paste is calcined by the heat in the submerged arc furnace. Therefore, the consumption speed of the electrode and the calcination speed are the key to the use of the electrode paste. As the ore furnace technology gradually develops toward large-scale and air-tight-ness, the electrode develops from the open furnace type to the closed furnace type during the calcining process, and the heat obtained by the electrode from the furnace is greatly reduced, which requires an increase in the sintering properties of the electrode paste to compensate for this deficiency.

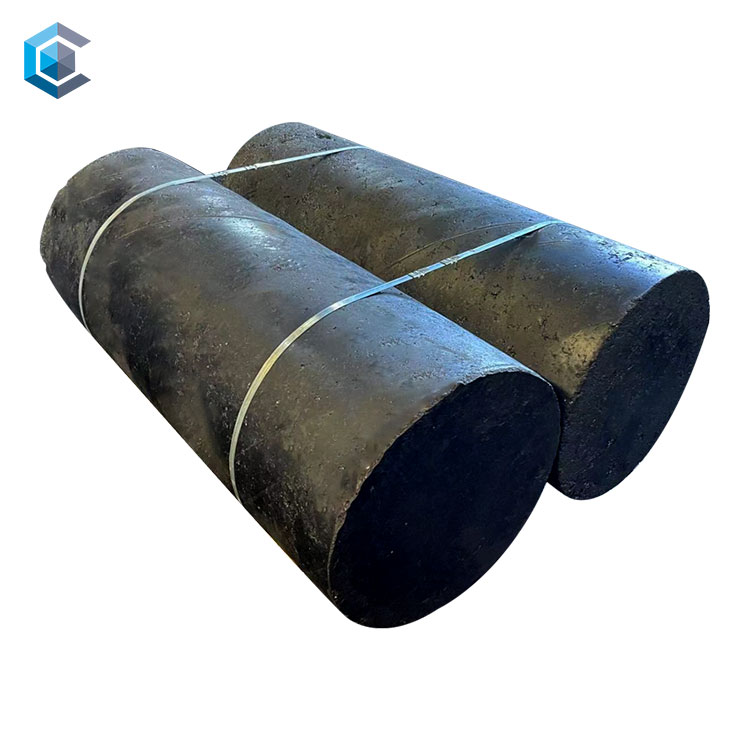

Electrode Paste Shape:

Egg Trapezoid Cylinder

Application:

Used in the electric equipment such as ferroalloys furnace, carbide furnace as a conductive material.

Advantages of Rongxing Electrode Paste:

Customization according to the customer's equipment and the type of ferroalloy being produced; private customization.

With the most advanced technology, production technology and testing technology. Professional after-sales service technical support and QC team.

The factory is in a good position and has all kinds of high-quality raw materials which can produce electrode paste.

Rongxing has a group of experts in the field of servicing Electrode Paste. All of our technicians are trained engineers that have worked in furnaces or within Electrode Paste manufacturers in the past. We know all of the EAF, Ladle, and Foundry applications throughout China and the world. Our experienced engineers offer an all-round support to the customers for taking our UHP electrodes into operation.They check and analyse the customers’ furnace conditions in order to achieve an optimal performance of the Electrode Paste and a decrease of the specific electrode consumption. Beyond the standard procedure of selling electrodes, such as signing contracts, providing third-party testing and regular after-sales service, we support customer in many ways. This includes signing warranty agreement, ensuring the product using effect, identifying a problem before it happens and solving the problem to relieve customers of worries.

Physical and chemical indexes of electrode paste

| Index | National Standard | Our Product | Unit/Notes |

|---|---|---|---|

| V.M (Volatile Matter) | 9-16% | 9-16% | % |

| Ash | < 2 | < 2 | - |

| Sulfur Content | < 1.5 | < 1.5 | % |

| Compressive Strength | > 18 | ~24 | MPa |

| Resistivity | - | < 70 | μΩ·m |

| Bulk Density | > 1.38 | > 1.45 | g/cm³ |

| Extensibility | 20-40 | ~30 | % |

| Softening Point | - | Customized | Varies based on customer furnace |

| Other Features | - | Low ash, high carbon content | - |

Common indicators in the Metallurgical industry

| English Name | Range/Value | English Name | Range/Value |

|---|---|---|---|

| Si (Silicon) | <0.28% | Fe (Iron) | <0.25% |

| P (Phosphorus) | 0.004% | ||

| Ash content | 2 - 10% | Resistivity | 55 - 90 μΩm |

| Volatile Matter | 10.0 - 15.0 | Density | >1.46g/cm³ |

| Compression Strength | >18Mpa | Extensibility | 6 - 20 |

| Apparent Density | >1.42g/cm³ | Rupture Strength | >4.0 |

| Real Density | >1.98g/cm³ | Fluidity Coefficient | 1.10 - 2.10 |

Phone:+86 19937179450

Phone:+86 19937179450

Whatsapp:+86 19937179450

Whatsapp:+86 19937179450

Email:

Email: Add:Zhengdong New District,Zhengzhou City,China.

Add:Zhengdong New District,Zhengzhou City,China.