The Ultimate Guide to Electrode Paste: Types, Formulation, and Export Excellence

In the world of submerged arc furnaces and electric smelting, the unsung hero is undoubtedly electrode paste. This self-baking carbon material is the vital conduit for electrical energy, powering the production of ferroalloys, silicon, calcium carbide, and more. Understanding the nuances of different electrode pastes is crucial for operational efficiency, cost-effectiveness, and superior product quality.

What is Electrode Paste?

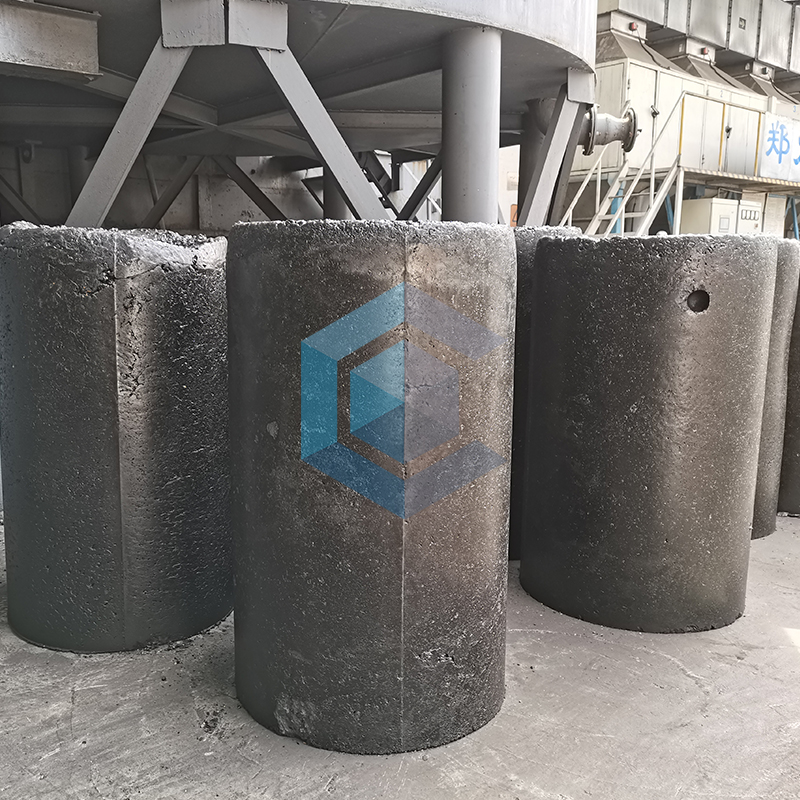

Electrode paste is a semi-solid, carbon-based material composed of solid carbon aggregates (like calcined anthracite or calcined coke) and a binder (typically coal tar pitch). It is loaded into the electrode shells of submerged arc furnaces, where it bakes in situ from the furnace's heat, forming a strong, conductive electrode that is continuously consumed and replenished.

A Deep Dive into Key Electrode Paste Types

The specific application dictates the ideal electrode paste formulation. Here’s a look at the most common types:

Ferro-silicon Electrode Paste & Silicon-manganese Electrode Paste: Formulated for high-temperature stability and specific resistivity to efficiently produce ferro-silicon and silicon-manganese alloys.

Calcium Carbide Electrode Paste: Designed to withstand the extreme conditions in calcium carbide furnaces, requiring high mechanical strength and consistent consumption.

Ferro-nickel Electrode Paste & Ferro-manganese Electrode Paste: These formulations are optimized for the unique chemical and thermal environments of ferronickel and ferromanganese smelting.

Direct Current (DC) Electrode Paste: Used in DC arc furnaces, this paste has distinct electrical and thermal properties compared to AC furnace pastes to handle the different current distribution.

Furnace Repair Electrode Paste: A specialized paste used for patching and repairing electrodes in situ, ensuring minimal furnace downtime.

Choosing the Right Raw Materials: Formulation Matters

The performance of an electrode paste hinges on its formulation. Two primary solid aggregate bases are:

Calcined Coke Electrode Paste: Known for its excellent electrical conductivity and purity, making it ideal for high-grade ferroalloy production.

Anthracite Electrode Paste: Offers a cost-effective solution with good performance, commonly used in standard-grade ferroalloy and calcium carbide production.

Expert electrode paste formulation is a science, balancing factors like particle size distribution, binder content, and additive chemistry to prevent issues like premature consumption or electrode paste caking.

Shapes for Optimal Performance: Beyond the Standard

To enhance furnace operation and sintering characteristics, electrode paste is available in various shapes:

Cylindrical Electrode Paste: The traditional and most common form.

Trapezoidal Electrode Paste: Offers better packing density within the electrode shell, reducing the risk of voids.

Egg-shaped Electrode Paste: Designed for smooth, automated feeding systems, improving operational safety and efficiency.

Your Partner in Electrode Paste Export

Navigating the global market for quality electrode paste requires a reliable partner. A professional Electrode Paste Plant with robust R&D and quality control is essential. Look for an electrode paste export supplier that offers:

A comprehensive range of products for diverse applications.

Technical support for formulation selection and troubleshooting.

Reliable logistics to ensure the product arrives in perfect condition, free from caking or damage.

PREVIOUS:Key Factors and Mechanisms of Electrode Paste Over-Consumption in Submerged Arc Furnaces

NEXT:There is no more content!

Phone:+86 19937179450

Phone:+86 19937179450

Whatsapp:+86 19937179450

Whatsapp:+86 19937179450

Email:

Email: Add:Zhengdong New District,Zhengzhou City,China.

Add:Zhengdong New District,Zhengzhou City,China.