what is electrode paste soft breakage

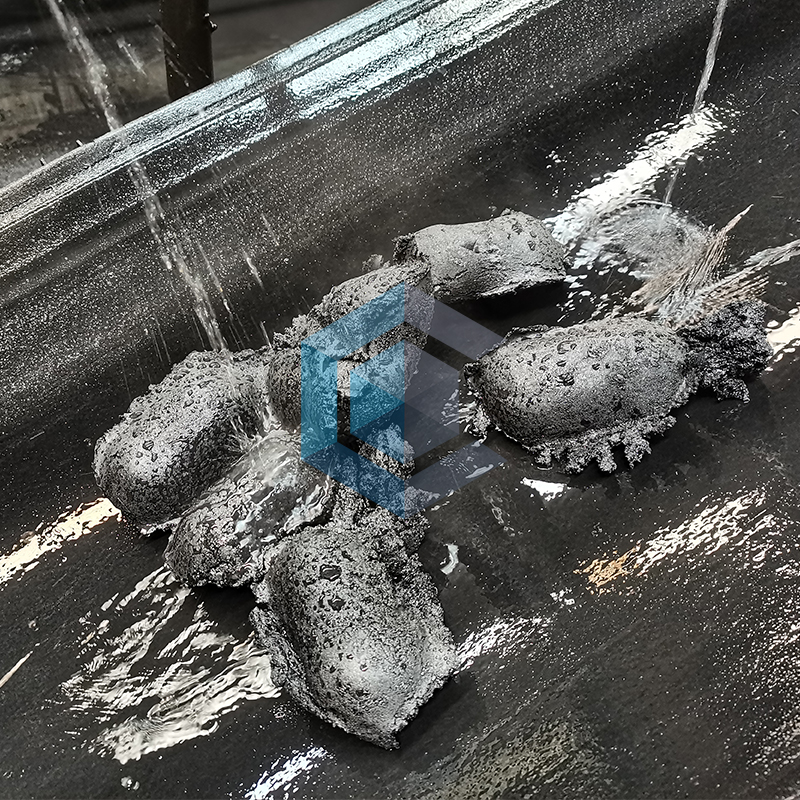

Electrode paste soft breakage refers to the phenomenon of electrode paste breaking in areas where it has not been fully sintered in equipment such as submerged arc furnaces.

Electrode paste soft breakage is a serious production accident. When a soft breakage occurs, the control panel in the central control room typically displays a sudden increase in the ammeter, or a sudden increase followed by a momentary decrease without recovery. Simultaneously, the electrode-to-furnace voltage drops to "0." Additionally, there may be heavy black smoke emanating from the electrode drum on the fourth floor, or yellow smoke emanating from the protective screen. There may also be a sudden increase in furnace gas outlet temperature and pressure.

Causes of electrode paste soft breakage include substandard electrode paste quality; inappropriate paste particle size; irregular paste addition resulting in loose or unsintered paste; substandard electrode drum welding quality; electrode baking speed being slower than the pressing and releasing speed; and excessive moisture in the raw materials causing material collapse. This article will analyze several potential causes of substandard electrode paste quality, focusing on electrode paste indicators:

Abnormal ratios of key electrode paste components

a. Excessively high/low volatile content: Volatiles (primarily lightweight components in coal tar pitch) serve as the "binder" for electrode paste sintering. Excessively high volatile content leads to rapid volatile release during sintering, creating numerous pores and reducing electrode strength. Excessively low content prevents effective bonding of solid particles, also resulting in a loose sintered body.

b. Excessively high ash content in electrode paste: Ash (inorganic impurities such as SiO₂ and Al₂O₃) does not participate in the sintering reaction. Excessively high ash content dilutes the effective bonding components, reducing electrode conductivity and mechanical strength, and making unsintered sections susceptible to brittle fracture.

c. Insufficient fixed carbon content in electrode paste: Fixed carbon is the core conductive and load-bearing component of the electrode. Low fixed carbon content results in low electrode density and poor strength, making the electrode unable to withstand its own weight and furnace pressure.

The softening point of the electrode paste does not match the sintering characteristics.

a. A too high softening point means the electrode paste has difficulty softening and flowing within the electrode cylinder, unable to fill the gaps between particles. This results in "delamination" or "voids," and the unsintered section has a loose structure.

b. A too low softening point means the electrode paste tends to soften and collapse prematurely, resulting in unstable paste column height and excessive sinking during press-out. The unsintered section can be forced into the furnace and then fracture.

Improper electrode paste particle size distribution.

Electrode paste is typically composed of a proportional mixture of coarse particles (5-10mm), medium particles (2-5mm), and fine powder (<2mm). A uniform particle size (e.g., too much fine powder) can lead to poor paste column permeability, preventing volatile matter from escaping smoothly and causing "internal bubbling." Excessive coarse particles can lead to loose bonding between particles, resulting in "gap formation." Both of these factors reduce electrode strength and can cause soft fracture.

The physical and chemical properties of the electrode paste directly determine its sintering performance. If these properties do not meet the requirements, soft breakage can occur even with proper operation. Rongxing Carbon's electrode paste production utilizes a precise mix of raw materials tailored to each customer's furnace type and production requirements. Our fully automated production line precisely controls the production process, ensuring the electrode paste specifications match the customer's furnace types. Over the past decade, Rongxing Carbon's electrode paste has never experienced a soft break during customer use.

PREVIOUS:Foreign Ferrosilicon Alloy Visits Rongxin Carbon to Inspect the Electrode Paste Production Process

NEXT:There is no more content!

Phone:+86 19937179450

Phone:+86 19937179450

Whatsapp:+86 19937179450

Whatsapp:+86 19937179450

Email:

Email: Add:Zhengdong New District,Zhengzhou City,China.

Add:Zhengdong New District,Zhengzhou City,China.